Products

Our Product Categories

At HSE our focus is on customer satisfaction. We believe that our success is determined by what we help our customers achieve. Since 1992 we have been providing quality products, engineering expertise, and professional service. Our customers know they can rely on HSE and our commitment to provide solutions that work. Contact us if you need assistance developing a custom monitoring solution. We offer many services including installation, maintenance, and data monitoring.

ALERT2

An array of solutions using ALERT2 technology

LEARN MORE

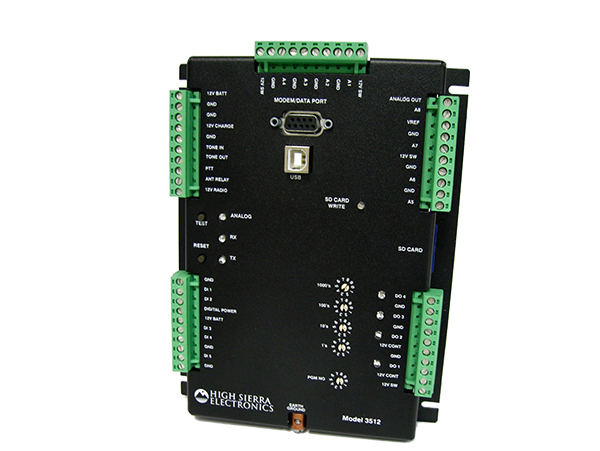

Transmitters / Loggers

Solutions to support a variety of applications

LEARN MORE

Road Weather Information Systems

State-of-the-art products for fixed and mobile road weather applications

LEARN MORE

Sensors

Broad range of sensors suited for applications requiring real-time environmental data

LEARN MORE

Mobile Devices

Mobile sensing technology for road weather applications

LEARN MORE

Mounting Structures

Equipment mounting structures for almost any application

LEARN MORE

Power Subsystems

Power management systems for remote monitoring sites

LEARN MORE

Communications

Communications that monitor environmental sensors and send control signals

LEARN MORE

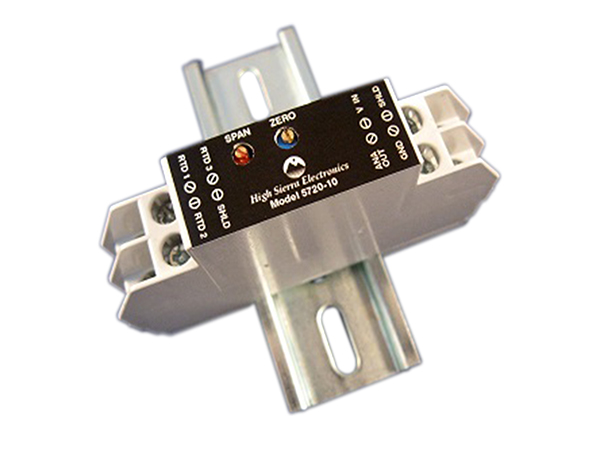

Signal Conditioning

Converts signals from one standard to another

LEARN MORE

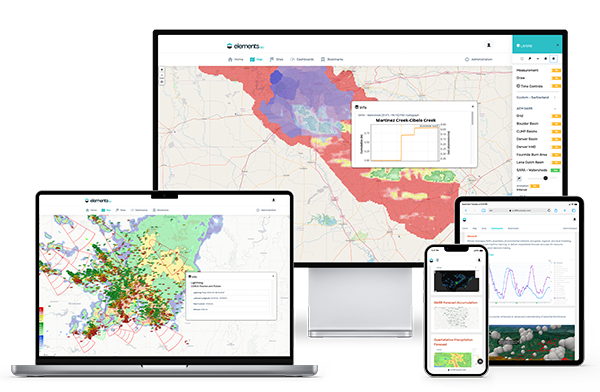

Software

Turns data into actionable decision making

LEARN MORE